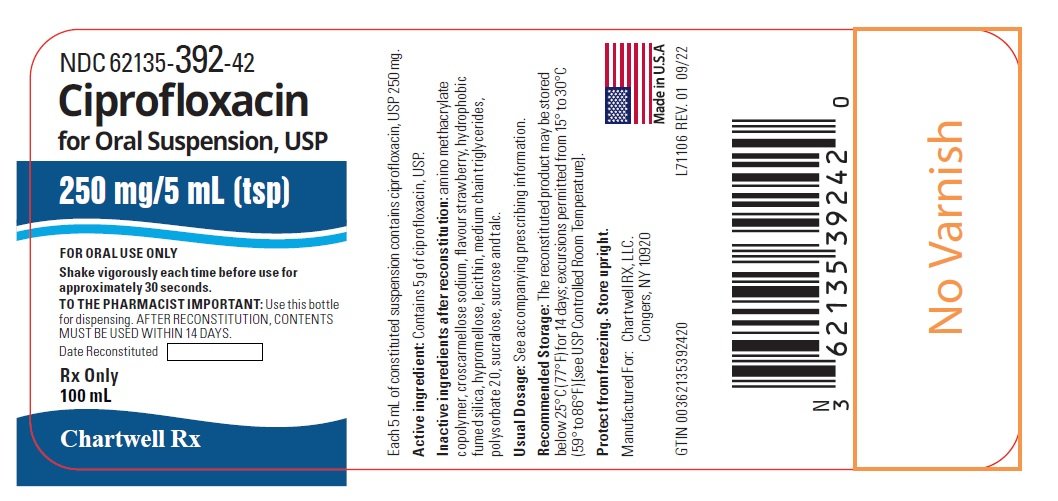

Need to compound ciprofloxacin suspension? Begin with precise measurements: target a concentration of 250 mg/5 mL for ease of dosing. This ensures accurate administration, particularly for pediatric patients.

Accurate weighing is paramount. Use a calibrated analytical balance for precise measurement of the ciprofloxacin powder. Any deviation can impact the final concentration and efficacy. Remember to account for any excipients like suspending agents (e.g., xanthan gum) to achieve optimal suspension properties.

Proper mixing technique is critical. Use a mortar and pestle to initially incorporate the ciprofloxacin into the suspending agent. Then, slowly add the vehicle (usually purified water) while continuously stirring to ensure a homogenous mixture. Avoid the formation of clumps for uniform dosing.

Sterility is non-negotiable. Employ aseptic techniques throughout the compounding process. This minimizes the risk of contamination and ensures the safety and efficacy of the final product. Use sterile equipment and a clean, controlled environment.

Finally, always confirm the final concentration via quality control testing to verify accuracy. This ensures the suspension meets the required specifications and is safe for administration. Thorough documentation, including all calculations and quality control results, is essential.

- Ciprofloxacin Suspension Compounding: A Detailed Guide

- Choosing the Right Vehicle

- Mixing and Dispensing

- Quality Control

- Common Challenges and Solutions

- Patient Counseling

- Calculating Ciprofloxacin Dosage for Pediatric Patients

- Compounding Ciprofloxacin Suspension: A Step-by-Step Procedure

- Stability and Storage of Compounded Ciprofloxacin Suspension

- Addressing Potential Challenges and Troubleshooting in Ciprofloxacin Suspension Compounding

Ciprofloxacin Suspension Compounding: A Detailed Guide

Always use sterile techniques. Begin by accurately weighing the ciprofloxacin powder using a calibrated analytical balance. Target a final concentration suitable for the patient’s age and weight, adhering to established pediatric dosing guidelines.

Choosing the Right Vehicle

Select a suitable suspending agent; Ora-Plus is frequently used, offering excellent suspension properties. Ensure its compatibility with ciprofloxacin. Carefully measure the vehicle, avoiding errors. A small amount of purified water may be needed to achieve desired viscosity.

Mixing and Dispensing

Gradually add the ciprofloxacin powder to the suspending agent, constantly stirring with a sterile spatula to avoid clumping. Use a mortar and pestle if needed to ensure complete dispersion. Once thoroughly mixed, transfer the suspension to a sterile amber glass bottle, properly labeling it with the patient’s name, concentration, dosage, and expiration date.

Quality Control

After compounding, visually inspect the suspension for homogeneity. There should be no visible clumps or settling. A stability study may be conducted for extended shelf-life verification. Properly store the compounded suspension to maintain potency. Refrigeration is usually recommended. Remember to always consult reliable references for detailed instructions and updated guidelines.

Common Challenges and Solutions

Inaccurate Weighing: Use a calibrated balance and double-check measurements. Clumping: Employ thorough mixing and possibly a different suspending agent. Stability Issues: Utilize proper storage conditions and consider adding preservatives if necessary (always within established guidelines). Remember to consult relevant literature and regulatory standards before initiating compounding.

Patient Counseling

Provide clear instructions on proper administration and storage of the suspension. Educate the patient about potential side effects and the importance of completing the prescribed course of treatment. Always stress the need for adherence to the prescribed dosage.

Calculating Ciprofloxacin Dosage for Pediatric Patients

Always consult the most current prescribing information for accurate dosing. Generally, Ciprofloxacin suspension for pediatric patients is calculated based on body weight. A common dosage is 10-20 mg/kg/day divided into two doses. For example, a 20 kg child would receive 200-400 mg daily, divided into two 100-200 mg doses.

Accurate weight measurement is critical. Use a calibrated scale to obtain the child’s weight in kilograms. This ensures precise dosage calculation.

Maximum daily dose: The maximum daily dose should not exceed 40 mg/kg/day. Never exceed this limit, even for severe infections. Always follow your doctor’s instructions.

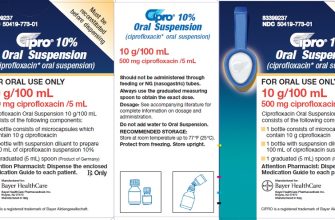

The prepared suspension’s concentration influences the volume administered. For a 250mg/5ml suspension, a 100mg dose requires 2ml. For a 500mg/5ml suspension, the same dose requires 1ml.

Administration: Administer the medication with food to minimize gastrointestinal upset. Shake the suspension well before each use to ensure uniform drug distribution.

Monitoring: Closely monitor the patient for adverse effects, including diarrhea, nausea, and vomiting. Report any unusual symptoms to the prescribing physician immediately.

This information is for educational purposes only and should not replace professional medical advice. Always consult a qualified healthcare professional for specific dosing instructions and to discuss potential risks and benefits for your individual child.

Compounding Ciprofloxacin Suspension: A Step-by-Step Procedure

First, accurately weigh the required amount of Ciprofloxacin powder using a calibrated balance. Ensure meticulous accuracy to maintain potency.

Next, add the appropriate amount of purified water to a suitable mortar and pestle. Gradually incorporate the Ciprofloxacin powder, ensuring complete wetting and dispersion to avoid clumping.

Then, transfer the suspension to a graduated cylinder. Add the necessary suspending agent, such as methylcellulose or xanthan gum, while continuously stirring gently. This ensures uniform distribution.

After that, adjust the final volume with purified water to achieve the desired concentration. Use a calibrated cylinder for precise measurements.

Finally, thoroughly mix the suspension using magnetic stirring or vigorous hand shaking to ensure homogeneity. Transfer the prepared suspension into an appropriate sterile container, label clearly with the concentration, patient name, and date of preparation.

Before dispensing, visually inspect the suspension for any visible particulate matter or inconsistencies. Discard if any issues are observed. Always follow strict aseptic techniques during the entire compounding process.

Stability and Storage of Compounded Ciprofloxacin Suspension

Store compounded ciprofloxacin suspension in a refrigerator at 2°C to 8°C (36°F to 46°F). This temperature maintains stability.

Discard the suspension after 14 days. A 14-day beyond-use date (BUD) ensures medication potency.

Use a light-resistant container to protect the suspension from degradation by light. Amber glass or opaque plastic bottles are suitable.

Tightly close the container after each use to prevent contamination and maintain the integrity of the medication. Air exposure can diminish effectiveness.

Always visually inspect the suspension before administration. Discard if you notice any changes in color, clarity, or the presence of particulate matter. This precaution ensures patient safety.

Follow USP 71 guidelines for sterile compounding practices during preparation and handling to minimize the risk of microbial contamination.

Accurate labeling is critical. The label must clearly indicate the medication name, concentration, BUD, and storage instructions. This ensures proper administration and reduces errors.

Patient education is vital. Instruct patients on proper storage and administration techniques, as well as the importance of adhering to the prescribed dosage and duration of therapy. This maximizes treatment success.

Addressing Potential Challenges and Troubleshooting in Ciprofloxacin Suspension Compounding

Accurate measurements are paramount. Use calibrated equipment like graduated cylinders and analytical balances to ensure precise drug concentration. Inaccurate measurements directly impact efficacy and patient safety.

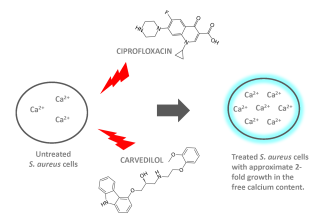

Solubility issues can arise. Ciprofloxacin’s solubility in water is limited. To enhance dissolution, consider using a suitable solubilizer like citric acid. Experiment with different concentrations to find the optimal balance between solubility and palatability.

Maintaining stability is crucial. Ciprofloxacin suspensions are susceptible to degradation. Store compounded suspensions under refrigeration (2-8°C) and protect them from light. Always check for any visible signs of degradation, such as discoloration or precipitation, before dispensing.

- Properly label containers with clear instructions regarding storage and administration.

- Advise patients on the correct storage conditions to maintain drug stability and potency.

- Dispense only the quantity needed and instruct patients on discarding any unused portion after the prescribed duration.

Achieving a palatable suspension is vital, especially for pediatric patients. The addition of palatable flavorings can greatly improve patient compliance. However, always verify the compatibility of flavoring agents with ciprofloxacin.

- Test different flavorings in small batches to ensure they do not affect the stability or solubility of the medication.

- Consider using sweeteners cautiously to control the overall osmolarity of the suspension.

- Document your findings and your chosen flavoring and its concentration in the compounding record.

Sterility is non-negotiable. Use aseptic techniques throughout the entire compounding process. Regularly sanitize equipment and work areas to minimize contamination risk.

Consult reliable resources like the USP (link to USP resources) and other reputable formularies for guidance. This provides up-to-date information on best practices and helps ensure you’re following the most current standards.